- Understanding Load Sharing and Paralleling

- Generator Redundancy and Paralleling Basics

- Benefits of Using Multiple Generators in Parallel

- Tips for Effective Generator Paralleling

- FAQs

- FAQ 1: What is load balancing and why is it important for multiple generators?

- FAQ 2: How does load balancing work with multiple generators?

- FAQ 3: What are the benefits of implementing load balancing with multiple generators?

- FAQ 4: Can I implement load balancing myself or should I seek professional assistance?

- FAQ 5: How do I choose the right load balancer for my multi-generator setup?

Understanding Load Sharing and Paralleling

What Is Load Sharing?

Load sharing refers to the distribution of electrical load across multiple power sources or generators in a grid system. This helps to control and balance the current flow in the system, ensuring efficient operation of the engine. When there is a high demand for electricity, load sharing allows multiple generators to work together, ensuring that the workload is evenly distributed among them. This helps to control the current and speed of the engine. This helps prevent overloading of the current engine and ensures a more efficient and reliable control of speed and power supply.

The Benefits of Load Sharing

Load sharing with redundant generator sets and parallel generators offers several benefits in terms of efficiency, reliability, scalability, and engine performance. Here are some key advantages:

- By distributing the load among multiple generators, load sharing enhances system reliability and control. If one load generator fails or requires maintenance, the other load generators can continue to supply power without interruption. This ensures control over load demands.

- Improved Efficiency: Load sharing optimizes the utilization of each generator by balancing the workload. This prevents any single load generator from being underutilized or overburdened, leading to improved fuel efficiency and reduced operating costs for meeting load demands.

- Scalability: Load sharing allows for easy scalability as additional generators can be added to meet increasing power demands. This flexibility makes the generator room suitable for applications where power requirements may vary over time. The generator sets in the generator room operate on the generator load sharing principle, ensuring a reliable and efficient power supply. Additionally, the redundant generator in the generator room provides an extra layer of backup power.

- Redundancy: With load sharing, redundant backup generators can be employed to provide an extra layer of protection against unexpected power outages or equipment failures.

- Fault Tolerance: Load sharing improves fault tolerance by introducing redundancy into the system with generator sets. If one generator experiences a fault or malfunctions, others can seamlessly take over its share of the load without disrupting the overall power supply.

Applications for Load Sharing

Load sharing is crucial in industries and settings that require a dependable and uninterrupted power supply, especially when utilizing generator sets.

- Data centers: Load sharing ensures continuous operation of critical IT infrastructure by distributing the electrical load across multiple backup generators.

- Hospitals: In healthcare facilities, load sharing guarantees uninterrupted power supply for life-saving medical equipment during emergencies.

- Construction sites: Load sharing enables the simultaneous operation of multiple heavy machinery and equipment, improving productivity and efficiency.

- Events and outdoor venues: Load sharing allows for the efficient distribution of power across different areas, ensuring a smooth operation for concerts, festivals, and other large-scale events.

How Do Load Sharing and Paralleling Work Together?

Load sharing often goes hand in hand with paralleling. Paralleling refers to the synchronization of multiple generators to operate as a single unit. When generators are paralleled, they work together to share the electrical load. This ensures that each generator contributes its fair share based on its capacity.

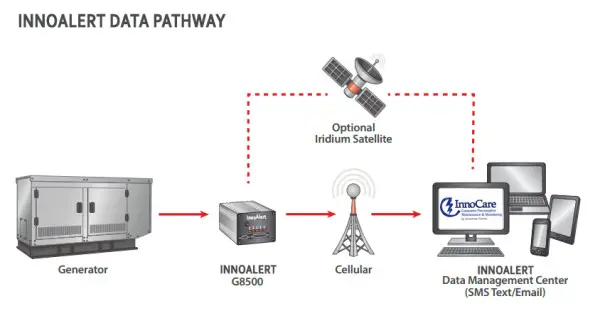

To achieve load sharing with paralleling, specialized control systems are used. These systems monitor the electrical load demand and adjust the output of each generator accordingly. They ensure that all generators operate at an equal level while maintaining voltage stability.

Generator Redundancy and Paralleling Basics

In the world of generators, redundancy and paralleling are essential concepts to understand. This section will delve into the basics of generator redundancy and running in parallel, as well as industrial generator paralleling and load sharing.

Generator Redundancy and Running in Parallel

Generator redundancy refers to having multiple generators available to provide power in case one fails or needs maintenance. Having a load generator is like having a backup plan for when things go wrong. The load generator helps with generator load sharing principle. By having redundant generators, you can ensure a continuous power supply even if one generator malfunctions.

Running generators in parallel takes redundancy to another level. Instead of relying on just one generator, you can connect multiple generators together so they work simultaneously. This allows for increased power output and load sharing between the generators.

Pros of Generator Redundancy and Running in Parallel:

- Increased reliability: With redundant generators, you have a backup power source ready to take over if one fails.

- Scalability: By adding more generators to the system, you can easily increase your power capacity as needed.

- Load sharing: When running generators in parallel, the workload is distributed among them, preventing overload on any single unit.

- Efficiency: Operating multiple smaller generators instead of one large generator can be more efficient since each unit operates closer to its optimal load.

Cons of Generator Redundancy and Running in Parallel:

- Higher cost: Implementing redundant systems with multiple generators can be more expensive upfront due to additional equipment and installation costs.

- Complex setup: Running generators in parallel requires careful synchronization and control systems to ensure proper load sharing.

- Maintenance challenges: Maintaining multiple generators can be more time-consuming and costly compared to maintaining a single unit.

- Potential for compatibility issues: Different generator models may not be compatible with each other for paralleling purposes.

Industrial Generator Paralleling and Load Sharing Basics

Industrial settings often require higher power capacities than residential or commercial applications. In these settings, a load generator is used to meet the increased power demands. The load generator operates based on the generator load sharing principle, ensuring efficient distribution of power. This is where industrial generator paralleling and load sharing come into play.

Industrial generator paralleling involves connecting multiple generators together to create a synchronized power system. These generators work in harmony, sharing the electrical load and ensuring a stable power supply for large-scale operations.

Load sharing is an integral part of industrial generator paralleling. It ensures that the workload is distributed evenly among the generators, preventing any single unit from being overloaded. Load sharing also helps optimize fuel consumption and reduces wear and tear on individual units.

Pros of Industrial Generator Paralleling and Load Sharing:

- Increased reliability: With multiple generators working together, there’s a higher level of redundancy, ensuring uninterrupted power supply.

- Scalability: Industrial generator paralleling allows for easy expansion of power capacity as needed.

- Efficient operation: Load sharing optimizes fuel consumption by distributing the workload evenly among generators.

- Flexibility: Parallel systems offer flexibility in terms of adding or removing generators based on changing power demands.

Cons of Industrial Generator Paralleling and Load Sharing:

- Implementing an industrial parallel system can be more expensive due to higher upfront costs associated with additional equipment, controls, and synchronization requirements of the load generator. The load sharing principle of the generator is a key factor in this increased cost.

- Complex setup and maintenance: The installation and maintenance of an industrial parallel generator load sharing system require specialized knowledge and expertise.

- Synchronization challenges: Ensuring proper synchronization between multiple generators can be challenging, requiring precise control systems.

Benefits of Using Multiple Generators in Parallel

Tips for Effective Generator Paralleling

FAQs

FAQ 1: What is load balancing and why is it important for multiple power plants?

Load balancing is the process of distributing the workload evenly across multiple generators in order to ensure efficient operation of the electrical grid. This is crucial for maintaining stability and preventing overloading of alternators in gas turbine power plants.

Load balancing refers to the distribution of workloads across multiple generators to optimize performance and prevent overloading. It ensures that each generator handles a fair share of the workload, improving efficiency and reducing downtime. Implementing load balancing with multiple generators is crucial for maintaining a stable power supply and preventing any single generator from becoming overwhelmed.

FAQ 2: How does load balancing work with multiple generators in paralleling switchgear?

Load balancing is a crucial aspect of operating multiple generators in parallel. When generators are connected to the electrical grid, they must work together efficiently to distribute the load evenly. This is achieved through the use of paralleling switchgear, which allows for the parallel operation of multiple generators. The switchgear ensures that each generator contributes its fair share of power to the grid, preventing any one generator from being overloaded. This load balancing process is particularly important when using gas turbines as

Load balancing works by intelligently distributing the workload among multiple generators based on their capacity and availability. A load balancer monitors the power demand and assigns tasks to different generators, ensuring an even distribution of load. This helps in maximizing utilization and achieving optimal performance by enabling generator load sharing, while minimizing stress on individual units.

FAQ 3: What are the benefits of implementing load balancing with multiple g3 gas turbine generators for the electrical grid and power solutions?

Implementing load balancing with multiple generators offers several advantages:

- Enhanced reliability: Load balancing ensures uninterrupted power supply by preventing any single generator from being overloaded or failing.

- Improved efficiency: By evenly distributing workloads, load balancing optimizes resource utilization, resulting in better overall efficiency.

- Scalability: Load balancing allows for easy scalability as additional generators can be added without disrupting operations.

- Flexibility: With load balancing, you have the flexibility to take one or more generators offline for maintenance or repairs while others continue operating seamlessly.

FAQ 4: Can I implement load balancing using my own controller hardware and software frequency, or should I seek professional assistance?

While it’s possible to implement basic load balancing techniques yourself, seeking professional assistance is highly recommended for complex setups involving multiple generators. Professionals possess expertise in designing and configuring robust load balancers tailored to your specific needs. Their experience in generator load sharing ensures optimal performance, compatibility with existing infrastructure, and adherence to industry best practices.

FAQ 5: How do I choose the right load balancer for my multi-generator setup with parallel generators? The load balancer is an essential component that ensures equal distribution of the load between the engines and maintains a stable grid connection. When choosing a load balancer for your setup, consider the specific requirements of each generator, including the engine type and the grid connection. The load balancer should be compatible with all parallel generators, including the G1 engine.

To choose the right load balancer for your multi-generator setup, consider the following factors:

- Scalability: Ensure the load balancer can handle your current and future power requirements as you expand your generator fleet.

- Redundancy: Look for load balancers with built-in redundancy features to ensure high availability and failover protection.

- Compatibility: Verify that the load balancer is compatible with your generators’ control systems and communication protocols.

- Support and maintenance: Check if the load balancer manufacturer offers reliable support services and regular software updates.

Ready to optimize your power generation? Contact our team of experts today for personalized guidance on implementing efficient load balancing solutions for your multiple generators.