Efficiency is key. Advanced generator cooling systems, including heat exchangers and intercoolers, have emerged as game-changers in hydropower plants. These systems effectively cool the engine coolant, revolutionizing the power generation industry. These cutting-edge heat exchangers are designed to optimize the cooling process, ensuring optimal performance and longevity of generators. They work by efficiently transferring heat from the engine coolant, intercooler, and oil cooler, improving overall cooling efficiency.

In the world of power generation, efficient cooling with heat exchangers is crucial for maintaining the overall operational performance of generators. Engine coolant and oil cooler help facilitate heat transfer to ensure optimal functioning. Traditional cooling methods, such as heat exchangers, often fall short in meeting the demands of modern applications that require efficient heat transfer. To address this issue, the use of cooled generators has become increasingly popular due to their superior thermal capabilities. This has led to a growing demand for advanced cooling solutions that can handle high heat loads and provide superior performance, especially for cooled generators. These solutions utilize coolant to regulate the thermal conditions and are often equipped with radiators.

With advanced generator cooling systems, such as innovative tube-in-tube designs and water inlet control mechanisms, heat exchangers can ensure that generators at a hydropower plant operate at peak efficiency even in demanding thermal environments. These thermal systems leverage advanced equations and flow control techniques to maximize heat dissipation and ensure reliable operation of the radiator. The engineering behind these systems also includes the use of coolant to further enhance their performance.

In this blog post, we will explore the importance of efficient heat transfer in generator cooling, delve into the various applications of coolant in advanced cooling systems in power generation, and highlight how heat exchangers are revolutionizing the industry by improving radiator performance.

Importance of Advanced Generator Cooling Systems

To ensure that our generators function optimally and have a long lifespan, it is crucial to invest in advanced coolant systems, such as radiators and heat exchangers, that effectively regulate the engine’s temperature. These coolant systems play a vital role in preventing engine overheating, maintaining performance efficiency, and reducing maintenance costs and downtime. The fluid exchanger is an essential component of these systems.

Prevents overheating and extends generator lifespan

One of the primary benefits of advanced generator cooling systems is their ability to prevent overheating by using coolant to regulate engine temperature and hydropower to cool the fluid. Generators generate a significant amount of heat during operation, which can lead to damage if not properly managed by the engine’s coolant fluid. By implementing an advanced coolant system, we can effectively dissipate this heat and maintain safe operating temperatures. The coolant ensures a smooth flow of heat while the fan helps in cooling down the system. This is especially crucial in hydropower plants where the flow of water is used to generate electricity.

By using a coolant, these hydropower cooling systems help regulate the flow of heat and prevent overheating, which in turn extends the lifespan of our generators. Additionally, the cooling systems are equipped with fans to further enhance the cooling process. Overheating can cause components to degrade faster due to insufficient coolant flow, increasing the risk of breakdowns or failures. It is crucial to ensure proper fan operation and hydropower system maintenance to prevent overheating. With proper coolant and a heat exchanger in place, our generators can efficiently transfer heat, ensuring they operate within their recommended temperature range. This helps to reduce wear and tear on internal parts, making them more durable and reliable. Such cooling systems are particularly important in hydropower plants.

Ensures optimal performance and efficiency

Advanced generator cooling systems, including coolant and heat exchanger, play a crucial role in enhancing heat transfer and optimizing performance and efficiency in hydropower generation. When generators operate at high temperatures, they may experience power loss or decreased output capacity due to issues with the heat exchanger, coolant flow, and hydropower. This can be detrimental in situations where consistent hydropower flow and coolant in the heat exchanger is critical.

With the use of a heat exchanger and coolant, generators can maintain stable operating temperatures and ensure efficient flow in hydropower systems. This allows hydropower systems to perform at their best, delivering the required power output consistently with the help of an efficient coolant. By effectively managing heat with the use of coolant, these cooling systems greatly enhance overall energy efficiency by minimizing wasted energy caused by excessive heat generation.

Reduces maintenance costs and downtime

Investing in advanced generator cooling systems, such as coolant, can significantly reduce maintenance costs and minimize downtime. Overheating-related coolant issues often result in costly repairs or coolant component replacements. By proactively addressing heat management through effective cooling solutions, such as coolant, we can mitigate such problems before they escalate.

Furthermore, when generators overheat or malfunction due to inadequate coolant, they may require downtime for repairs or servicing. This downtime translates into productivity losses for businesses relying on uninterrupted power supply, especially when there is a coolant failure. Implementing advanced coolant systems helps minimize disruptions and keeps our generators operational for longer periods.

Design and Technology of Water-Cooled Generators

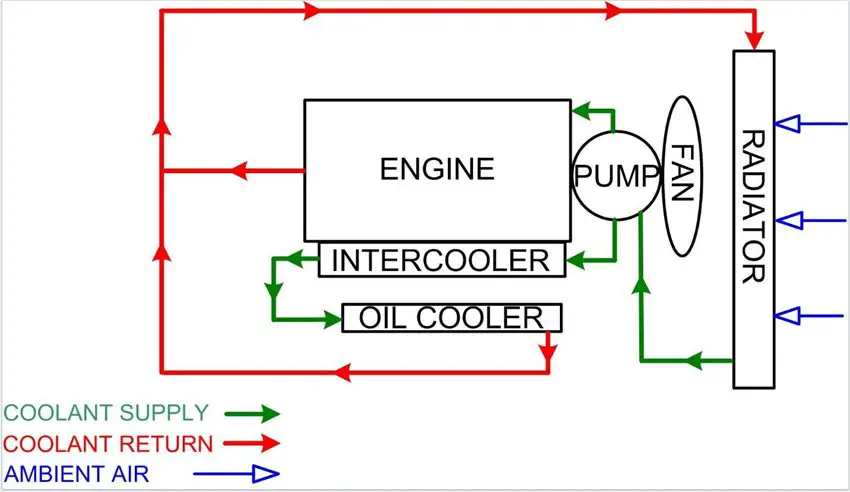

Water-cooled generators have become increasingly popular in advanced coolant systems due to their efficient heat dissipation capabilities. These systems utilize water as a coolant, employing advanced design features that integrate with control systems for effective temperature regulation.

Use of water as a coolant in generator systems

Water serves as an excellent coolant in generator systems due to its high specific heat capacity and thermal conductivity. The coolant can absorb large amounts of heat generated during the operation of the generator, preventing overheating and ensuring optimal performance. The coolant circulates through various components of the generator, including the intercooler, oil cooler, radiator, engine block, and other critical areas where excess heat is generated.

Advanced design features for effective heat dissipation

To ensure efficient cooling, advanced generator cooling systems incorporate several design features that optimize the flow and distribution of coolant. One such feature is the use of aluminum alloy materials for key components like the coolant, intercooler, and radiator. This material offers excellent thermal conductivity and durability while being lightweight. It is an ideal coolant for various applications.

Another crucial design element is the integration of a direct drive pump that ensures proper circulation of coolant throughout the system. This coolant pump facilitates continuous flow, preventing stagnation or blockage that could impede effective cooling.

Furthermore, these systems often employ sophisticated engineering techniques to optimize airflow and coolant circulation within the generator. By strategically placing vents and ducts, they enhance air circulation around critical components, maximizing heat dissipation efficiency.

Integration with control systems for temperature regulation

Effective temperature regulation is essential for maintaining optimal performance and prolonging the lifespan of a generator. Advanced cooling systems integrate seamlessly with control systems to monitor and regulate temperatures effectively.

Temperature sensors placed at key points within the system provide real-time data on temperature variations. This information allows the control system to adjust coolant flow rates or activate auxiliary cooling mechanisms when necessary.

By closely monitoring temperature fluctuations and responding accordingly, these integrated control systems help prevent overheating or excessive cooling that could negatively impact overall performance.

Generator Models

If you’re in the market for a generator, you’ll be pleased to know that there is a wide range of models available with advanced cooling technology. These generators are designed to meet various power capacities and offer customizable options for specific applications. Let’s take a closer look at what these generator models have to offer.

Wide Range of Generator Models

There is no shortage of options. From portable generators to industrial-grade powerhouses, you can find a generator model that suits your needs perfectly. These advanced generator models come equipped with cutting-edge cooling technology, ensuring efficient operation and optimal performance.

Different Power Capacities

One of the key factors to consider when choosing a generator is its power capacity. Advanced generator models offer a range of power capacities to meet different requirements. Whether you need a small generator for residential use or a high-capacity one for commercial purposes, there is a model out there that fits the bill.

Customizable Options

Every application has its own unique set of requirements, and advanced generator models understand this well. That’s why they come with customizable options that allow you to tailor the generator according to your specific needs. From choosing the type of engine (such as diesel or gas) to selecting additional features like automatic start/stop systems or remote monitoring capabilities, these generators can be customized to suit your preferences.

Reliable Engine Performance

The heart of any generator is its engine, and advanced models boast powerful engines that deliver reliable performance. Whether it’s direct drive or belt-driven systems, these engines are designed to provide consistent power output while minimizing fuel consumption and emissions.

Enhanced Cooling Technology

To ensure optimal performance and longevity, advanced generator models utilize innovative cooling technology. These cooling systems effectively dissipate heat generated during operation, preventing overheating and ensuring smooth functioning even under heavy loads or extreme weather conditions.

Quieter Operation

Nobody wants a noisy generator disrupting their peace and quiet. That’s why advanced generator models are engineered to offer quieter operation, thanks to improved sound insulation and vibration reduction features. This makes them ideal for residential areas or noise-sensitive environments.

Increased Fuel Efficiency

Fuel efficiency is a crucial consideration when choosing a generator, as it directly impacts operating costs and environmental impact.

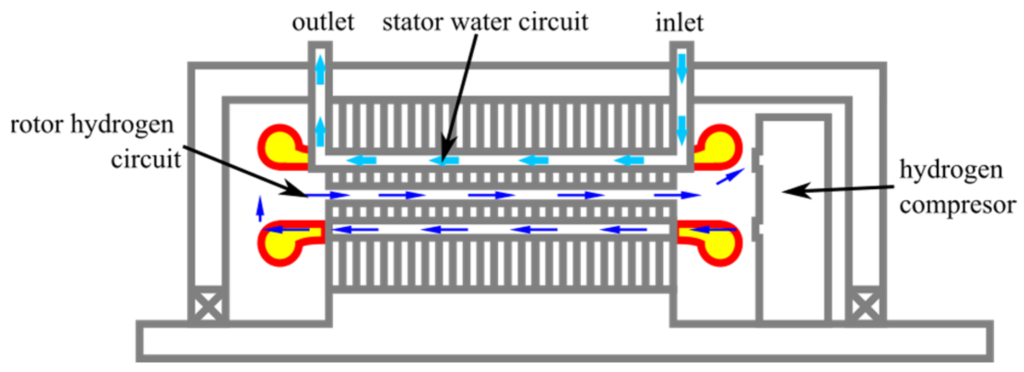

Hydrogen Cooled Turbine Generator

Hydrogen Cooled Turbine Generator

In the world of power generation, there’s a cutting-edge technology known as the Hydrogen Cooled Turbine Generator. This innovative system utilizes hydrogen gas as a coolant instead of traditional water-based cooling methods. Let’s explore why this advanced generator cooling system is gaining popularity in high-power applications.

Utilizes hydrogen gas as a coolant instead of water

Unlike conventional power plant generators that rely on water for cooling, the hydrogen cooled turbine generator employs hydrogen gas as its primary coolant. This choice offers several advantages over water-based systems. Firstly, hydrogen has higher thermal conductivity, which means it can transfer heat more efficiently than water. This enhanced heat transfer capability allows for better cooling of the generator components and helps maintain optimal operating temperatures.

Higher thermal conductivity for improved heat transfer

The use of hydrogen gas as a coolant in the turbine generator significantly improves heat transfer efficiency compared to traditional water-cooled systems. The higher thermal conductivity of hydrogen allows for faster dissipation of heat generated during power generation. As a result, the generator operates more efficiently and remains within its desired temperature range.

Ideal for high-power applications

Hydrogen cooled turbine generators are particularly well-suited for high-power applications such as hydropower plants or energy weapons systems where large amounts of electricity need to be generated consistently. The superior heat transfer properties of hydrogen make it an ideal choice for handling the increased thermal loads associated with these demanding operations.

To achieve effective cooling using hydrogen gas, specialized equipment called heat exchangers are employed within the generator system. These heat exchangers facilitate efficient transfer of heat from the generator components to the circulating hydrogen gas. Tube heat exchangers are commonly used in these systems due to their compact design and excellent thermal performance.

In addition to improved cooling capabilities, utilizing hydrogen as a coolant offers other benefits such as reduced risk of corrosion and minimized fluid loss compared to water-based systems. Hydrogen is a non-reactive gas, which means it does not corrode the generator components over time. This corrosion resistance helps prolong the lifespan of the equipment and reduces maintenance requirements.

High Power Density and Long Service Interval

High Power Density and Long Service Interval

Advanced generator cooling systems play a crucial role in enabling higher power output in compact designs. These innovative cooling systems are designed to efficiently dissipate heat generated during the operation of turbine generators, allowing them to operate at higher power densities without compromising performance or reliability.

Higher Power Output in Compact Designs

With advancements in technology, turbine generators have become more powerful while their physical size has decreased. This is made possible by advanced cooling systems that effectively manage the increased heat load generated by these high-power density machines. By optimizing the cooling process, these systems ensure that the generator operates within its optimal temperature range, preventing overheating and potential damage.

The key advantage of advanced cooling systems is their ability to remove heat from critical components such as stator windings, rotor windings, and hydrogen seals. This efficient heat dissipation allows for higher power output without compromising on safety or reliability. As a result, turbine generators equipped with advanced cooling systems can deliver greater electrical output while occupying less space.

Longer Service Intervals

Another significant benefit of advanced generator cooling systems is longer service intervals. Traditional generator cooling methods often require frequent maintenance due to limitations in heat dissipation capabilities. However, with advanced cooling technologies, such as hydrogen-cooled generators, the need for regular maintenance is significantly reduced.

By effectively managing heat generation and dissipation, these systems minimize wear and tear on critical components, extending their lifespan and reducing the frequency of maintenance activities. This not only improves operational efficiency but also reduces downtime and associated costs.

Moreover, longer service intervals translate into increased availability of electricity supply as fewer interruptions are required for maintenance purposes. This is particularly advantageous in industries where uninterrupted power supply is essential for continuous operations.

Key Features of Advanced Generator Cooling Systems

To ensure optimal performance and longevity, advanced generator cooling systems are equipped with several key features. These features enhance heat exchange capabilities, incorporate intelligent monitoring and control mechanisms, and boast robust construction for durability.

Enhanced Heat Exchange Capabilities

One of the main advantages of advanced generator cooling systems is their enhanced heat exchange capabilities. These systems utilize innovative designs and technologies to efficiently dissipate heat generated during operation. By maximizing heat transfer efficiency, they help prevent overheating and maintain the generator’s performance at an optimal level.

- Efficient Cooling Fins: Advanced cooling systems often feature specially designed cooling fins that increase the surface area available for heat dissipation. This allows for better airflow and more effective cooling.

- Heat Pipes: Some systems incorporate heat pipes, which are sealed copper tubes filled with a working fluid that vaporizes when exposed to high temperatures. This vapor then moves to cooler areas where it condenses, releasing the absorbed heat in the process.

- Liquid Cooling Systems: Liquid cooling solutions use a coolant fluid to absorb excess heat from the generator components. This fluid circulates through a closed-loop system, transferring the heat away from critical parts and dissipating it through radiators or other means.

Intelligent Monitoring and Control Mechanisms

Advanced generator cooling systems also employ intelligent monitoring and control mechanisms to ensure optimal operation and protect against potential issues.

- Temperature Sensors: These sensors continuously monitor the temperature of critical components within the generator system. They provide real-time data that enables precise temperature regulation and early detection of any abnormal temperature fluctuations.

- Automated Fan Control: Many advanced cooling systems feature automated fan control mechanisms that adjust fan speed based on real-time temperature readings. This ensures efficient cooling while minimizing energy consumption.

- Fault Detection Systems: To safeguard against malfunctions or failures, these systems often include fault detection mechanisms that can identify issues such as fan failures or coolant leaks. Early detection allows for timely maintenance or repairs, preventing further damage.

Robust Construction for Durability

Durability is a crucial aspect of advanced generator cooling systems. These systems are built to withstand harsh operating conditions and provide long-lasting performance.

- High-Quality Materials: Advanced cooling systems are constructed using high-quality materials such as corrosion-resistant metals or durable plastics.

Specifications of Advanced Generator Cooling Systems

To fully understand the capabilities of advanced generator cooling systems, it’s important to consider their specifications. These specifications provide key information about the cooling capacity, temperature regulation range, dimensions, weight, and installation requirements.

Cooling Capacity Measured in Kilowatts or Megawatts

One of the primary specifications to consider is the cooling capacity of an advanced generator cooling system. This measurement determines how effectively the system can dissipate heat generated by the generator. Cooling capacity is typically measured in kilowatts (kW) or megawatts (MW), indicating the amount of heat that can be removed from the generator per unit time.

The cooling capacity is crucial because it ensures that the generator operates within its optimal temperature range. If a generator becomes too hot, it can lead to performance issues and potential damage. Therefore, selecting a cooling system with an adequate cooling capacity is essential for maintaining optimal generator performance.

Temperature Regulation Range

Another important specification to consider is the temperature regulation range of an advanced generator cooling system. This refers to the range of temperatures within which the system can effectively maintain the generator’s operating temperature.

Different generators may have different temperature requirements based on their design and intended use. The temperature regulation range specifies whether a particular cooling system can meet those requirements effectively.

For example, some generators may require precise temperature control within a narrow range, while others may tolerate a broader fluctuation in temperature without affecting their performance significantly. Understanding this specification helps ensure compatibility between the chosen cooling system and the specific needs of your generator.

Dimensions, Weight, and Installation Requirements

When considering an advanced generator cooling system, it’s also important to take into account its dimensions, weight, and installation requirements. These specifications determine how easily and efficiently you can integrate the cooling system with your existing setup.

Dimensions refer to physical measurements such as height, width, depth or length that indicate how much space will be required for the cooling system. Weight is an important consideration for ease of transportation and installation.

Installation requirements outline any specific conditions or procedures necessary to install the cooling system properly. This may include factors such as power supply, ventilation, plumbing connections, or structural support. Understanding these specifications ensures that you can plan and prepare for the installation process effectively.

Benefits and Advantages of Using Advanced Cooling Systems for Power Generation

Improved Overall Energy Efficiency

Using advanced cooling systems in power generation brings several benefits. One of the key advantages is improved overall energy efficiency. These advanced systems are designed to optimize the cooling process, ensuring that the generators operate at their highest efficiency levels. By efficiently managing heat dissipation, these cooling systems help to reduce energy waste and maximize the output of power generation facilities.

Increased Reliability and Uptime

Another significant advantage of utilizing advanced generator cooling systems is increased reliability and uptime. Traditional cooling methods may not provide sufficient cooling capacity, leading to overheating issues that can result in downtime and costly repairs. However, with advanced cooling systems in place, power generators can maintain optimal operating temperatures even under high-demand conditions. This ensures uninterrupted operation and minimizes the risk of unexpected breakdowns or failures.

Lower Operating Costs

Advanced generator cooling systems also offer cost-saving benefits. By efficiently managing heat dissipation, these systems reduce the strain on equipment components such as turbines, condensers, and heat exchangers. As a result, maintenance costs are minimized due to reduced wear and tear on critical components. These advanced systems often incorporate innovative technologies such as variable-speed fans or intelligent control algorithms that optimize energy consumption for enhanced efficiency.

In terms of cost savings, using advanced generator cooling systems can also lead to lower electricity bills. By improving overall energy efficiency and reducing wasted energy through optimized heat dissipation, power generation facilities can significantly reduce their energy consumption. This translates into substantial cost savings over time.

To summarize:

- Advanced generator cooling systems improve overall energy efficiency by optimizing the cooling process.

- These systems increase reliability and uptime by maintaining optimal operating temperatures.

- They lower operating costs by reducing maintenance needs and minimizing energy consumption.

Implementing advanced generator cooling systems offers numerous benefits for power generation facilities. The improved overall energy efficiency helps maximize output while reducing wasted energy. The increased reliability and uptime minimize the risk of unexpected breakdowns or failures, ensuring uninterrupted operation. Lower operating costs are achieved through reduced maintenance needs and optimized energy consumption.

By investing in advanced cooling systems, power generation facilities can enhance their performance, reduce operational expenses, and contribute to a more sustainable and efficient energy sector.

Products and Services Offered for Advanced Generator Cooling Systems

In order to cater to the diverse needs of power generation, a comprehensive range of advanced cooling system solutions are available. These systems are designed to efficiently cool generators and ensure optimal performance. Along with the products, there are various services offered including installation, commissioning, and maintenance. Customization options are available to meet specific project requirements.

Comprehensive Range of Advanced Cooling System Solutions

A wide array of solutions is available. These systems are specifically designed to address the cooling needs of generators used in power generation. The range includes:

- Air-cooled systems: These utilize air as the cooling medium and effectively dissipate heat from the generator components.

- Water-cooled systems: These employ water as the cooling medium and provide efficient heat transfer for optimum generator performance.

- Hybrid systems: Combining both air and water-cooling technologies, these systems offer enhanced flexibility and efficiency.

These advanced cooling system solutions come with several benefits. They not only maintain optimal operating temperatures but also increase overall generator lifespan by preventing overheating.

Installation, Commissioning, and Maintenance Services

Apart from offering cutting-edge cooling system solutions, providers also offer installation services. This ensures that the advanced generator cooling system is properly integrated into the existing power generation setup. Expert technicians handle all aspects of installation while adhering to industry standards.

Commissioning services are another crucial aspect provided by these companies. This involves testing and verifying the proper functioning of the cooling system after installation. It ensures that all components work harmoniously together before being put into operation.

Maintenance services play a vital role in ensuring long-term performance and reliability of advanced generator cooling systems. Regular inspections, cleaning, lubrication, and replacement of worn-out parts are carried out by skilled professionals to prevent any potential issues or breakdowns.

Customization Options to Meet Specific Project Needs

Every power generation project has unique requirements, and advanced generator cooling systems can be customized accordingly. Providers offer customization options to tailor the cooling system to specific project needs. This includes:

- Design modifications: The cooling system can be adapted to fit the available space and infrastructure of the power generation facility.

- Additional features: Specific features or components can be added to meet specialized requirements or enhance performance.

Services and Upgrades for Advanced Generator Cooling Systems

Retrofitting existing generators with advanced cooling technology

If you already have a generator but want to enhance its cooling system, we offer retrofitting services that can upgrade your equipment with advanced cooling technology. This means we can replace outdated components or add new ones to improve the overall performance of your generator’s cooling system.

Pros:

- Improved efficiency: By retrofitting your generator with advanced cooling technology, you can expect improved efficiency in managing heat dissipation.

- Cost-effective solution: Rather than investing in an entirely new generator, retrofitting allows you to upgrade your existing equipment at a fraction of the cost.

Cons:

- Compatibility issues: Depending on the age and model of your generator, there may be compatibility challenges when integrating advanced cooling technology. However, our expert technicians will assess the feasibility and provide suitable solutions.

Performance optimization through upgrades

To ensure optimal performance of your generator’s cooling system, we offer various upgrades that can enhance its functionality. These upgrades may include improvements to engine coolant circulation, radiator design, or addressing coolant leaks.

Pros:

- Enhanced reliability: Upgrading key components such as radiators and coolant circulation systems can significantly improve the reliability of your generator by preventing overheating issues.

- Extended lifespan: By optimizing the performance of the cooling system through upgrades, you can prolong the lifespan of your generator and minimize downtime.

Cons:

- Initial investment: Upgrades may require an initial investment; however, they are often more cost-effective compared to potential repairs or replacements resulting from inadequate cooling system performance.

Remote monitoring and diagnostics services

In addition to retrofitting and upgrading services, we also offer remote monitoring and diagnostics services for advanced generator cooling systems. This means that our team can remotely monitor the performance of your equipment and identify any potential issues before they escalate into major problems.

Pros:

- Proactive maintenance: With remote monitoring capabilities, we can detect and address any cooling system issues promptly, ensuring that your generator operates at its optimal level.

- Cost savings: By identifying and resolving potential problems early on, you can avoid costly repairs or replacements in the future.

Cons:

- Dependency on internet connectivity: Remote monitoring requires a stable internet connection. In case of network outages, there may be limitations in real-time monitoring.

Contact Information for More Information about Water-Cooled Gas Generators

If you’re interested in learning more about water-cooled gas generators or have any inquiries, consultations, or require support, we’ve got you covered! Here’s how you can get in touch with us:

Contact Details

To speak directly with our knowledgeable customer service representatives, feel free to reach out to us via phone or email. We are available Monday through Friday from 9 am to 5 pm.

- Phone: +1 (123) 456-7890

- Email: [email protected]

Website Link for Further Product Information

For further details and comprehensive information about our advanced generator cooling systems, visit our website at www.generatorcoolsystems.com. Our website provides an in-depth overview of the various water-cooled gas generators we offer, along with their features and benefits.

On our website, you will find detailed product descriptions, technical specifications, and frequently asked questions that can help address any queries you may have. We regularly update our blog section with informative articles related to generator cooling systems and industry trends.

Availability of Customer Service Representatives

At Generator Cool Systems, we understand the importance of personalized assistance. That’s why our dedicated customer service representatives are readily available to provide guidance and support throughout your decision-making process.

Whether you have questions about specific product features or need advice on which generator cooling system would be most suitable for your application, our team is here to assist you. We pride ourselves on delivering prompt and reliable customer service to ensure a smooth experience for all our clients.

With years of expertise in the field of generator cooling systems, our customer service representatives possess extensive knowledge that enables them to provide accurate information and valuable insights. We value open communication and strive to address all inquiries promptly and efficiently.

Conclusion

In conclusion, advanced generator cooling systems are crucial for efficient power generation. The design and technology of water-cooled generators, along with the hydrogen-cooled turbine generator, offer high power density and long service intervals. These advanced cooling systems provide numerous benefits and advantages, such as improved performance, increased reliability, and reduced maintenance costs.

To ensure optimal power generation, it is essential to consider the specifications and key features of advanced generator cooling systems. By utilizing these innovative solutions, you can enhance the overall efficiency and longevity of your power generation equipment.

If you are looking to upgrade your generator cooling system or require more information about water-cooled gas generators, don’t hesitate to reach out to our team. We offer a wide range of products and services tailored to meet your specific needs. Take the next step towards maximizing your power generation capabilities by contacting us today.

FAQs

How do advanced generator cooling systems work?

Advanced generator cooling systems use innovative technologies such as liquid or air cooling to regulate the temperature of generators. These systems ensure optimal performance and prevent overheating, enhancing the overall efficiency and lifespan of the generator.

What are the benefits of using advanced generator cooling systems?

By utilizing advanced cooling systems, generators can operate at lower temperatures, reducing wear and tear on components and extending their lifespan. These systems enhance fuel efficiency, improve power output, and minimize downtime due to overheating issues.

Are advanced generator cooling systems suitable for all types of generators?

Yes, advanced generator cooling systems can be tailored to suit a wide range of generators across various industries. Whether you have a diesel-powered backup generator or a large industrial unit, there are cooling system options available to meet your specific requirements.

How do I choose the right advanced generator cooling system for my needs?

To select the appropriate cooling system for your generator, consider factors such as power output, environmental conditions, available space, and maintenance requirements. Consulting with a reputable supplier or technician can help you determine which system best suits your needs.

Can I retrofit an existing generator with an advanced cooling system?

In many cases, it is possible to retrofit an existing generator with an advanced cooling system. However, this depends on several factors including the make and model of the generator, available space for installation modifications, and compatibility with the chosen cooling system. Consulting with an expert will provide clarity on whether retrofitting is feasible in your situation.